- Pressure transducers measure and monitor pressure levels, providing essential insights into exact material quantities for calibrated homogeneous products.

- Computer-Aided Design/ Manufacturing (CAD/CAM) Systems automate the design process, ensuring accuracy and a level of precision impossible with manual methods.

- Automated Optical Inspection (AOI) Equipment helps to detect defects and errors quickly and accurately.

- Robotic arms with vision systems provide precise work in repetitive tasks such as welding, cutting, and painting.

Accuracy is critical in manufacturing, and the right equipment can make all the difference. With this equipment, manufacturers can produce high-quality parts with consistent results. This article will explore the various equipment types used to ensure accuracy in manufacturing today.

Pressure Transducers

Pressure transducers are an invaluable tool in manufacturing, as they ensure that all materials are produced to precise specifications. In essence, these devices measure and monitor pressure levels across varied applications.

The data generated by reliable pressure transducers provide essential insights into the exact quantities of material that should be used and helps manufacturers to calibrate homogeneous products.

During production, for instance, these instruments can provide accurate feedback on pressure conditions within pipelines or tanks. Furthermore, due to their dimensional stability, these devices guarantee more consistent results and promote quality assurance during all stages of production.

Automation Tools

Here are some automation tools that ensure accuracy in manufacturing:

Computer-Aided Design/ Manufacturing (CAD/CAM) Systems

Computer-Aided Design/Manufacturing (CAD/CAM) systems combine software, hardware, and people working to create fabrication or manufacturing designs. By leveraging this specialized process utilizing computers, items can be designed with exact specifications, ensuring a level of accuracy that is impossible through manual methods.

In addition, CAD/CAM offers a variety of optimization capabilities when it comes to materials usage and risk assessment. This means fewer errors during production and greater longevity for the finished objects.

Perhaps most importantly, CAD/CAM enables manufacturers to save time by automating the design process, which also helps keep costs lower than if designers were working singularly to create custom pieces every single time.

Automated Optical Inspection (AOI) Equipment

Automated optical inspection (AOI) equipment is an essential tool in manufacturing, designed to help ensure accuracy in the production process. AOI uses sensors and automated controls alongside visual inspection to identify defects and errors quickly and accurately. This helps to reduce costs due to fewer costly defects making it through to the end product.

AOI can also detect cosmetic and engineering flaws that may not be picked up by traditional manual or visual inspection methods, leading to higher quality assurance in the finished product. Furthermore, this technology has quick analysis times and high detection rates, resulting in more efficient work processes without sacrificing accuracy.

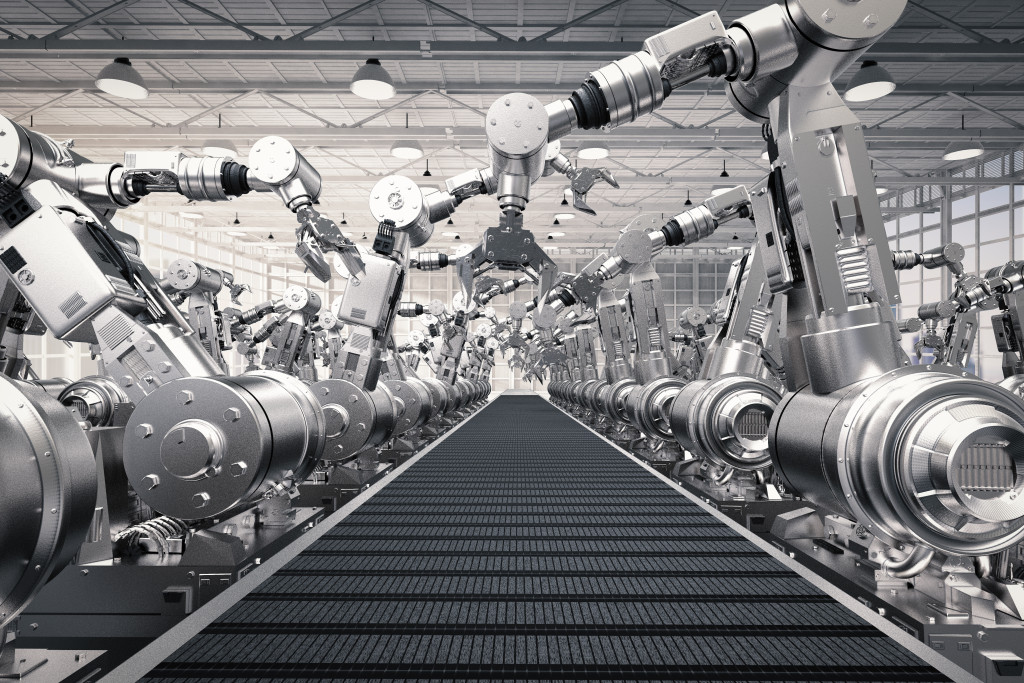

Robotic Arms with Vision Systems

Robotic arms with vision systems are essential pieces of equipment in manufacturing. The combination of robotic arms and vision systems in the same machine allows for repetitive tasks such as welding, cutting, and painting to be done more accurately and consistently than manual operations alone can achieve.

This is thanks to the camera unit installed onto these machines, including high-speed sensors, algorithms, and adaptability capabilities that manage the accuracy of movement and orientation of the robot arm. Not only does this ensure precise work, but it also helps manufacturers save costs since there is not much labor involved when using robotic arms with vision systems.

Laser Cutting and Engraving Machines

Laser cutting and engraving machines are essential equipment used in manufacturing: they provide high accuracy and precision in producing components or parts. Lasers use a focused, directional beam of light that can detect movements at small fractions of a millimeter, making them ideal for cutting materials such as metal plating, plastics, rubbers and stone with extreme accuracy.

This technology also eliminates manual errors and makes the process faster since it requires minimal setup time, allowing mass-production scenarios with high consistency. On top of that, laser cutting and engraving provide for an easier integration into automated assembly lines. For all these reasons, modern manufacturing could not operate without lasers; they have become an integral part of production processes everywhere.

3D Printers

3D printers are revolutionizing the manufacturing process. These computerized machines can create exact and accurately dimensioned objects, created layer by layer. This makes them ideal for creating parts and prototypes in various materials such as plastic, metal, ceramic, and other composites.

The ability to quickly produce intricate parts with unparalleled accuracy is invaluable for manufacturers requiring pinpoint precision to produce reliable products. 3D printing systems have enabled us to build items that could have never been produced – from custom medical prostheses to aerospace engine components. With an increasing number of manufacturers leveraging digital technology like 3D printing, it’s clear that these devices are critical for ensuring accuracy in mass production.

These are just a few of the technologies that are helping to ensure accuracy in manufacturing today. By combining various equipment, manufacturers can create reliable products at reduced costs while complying with stringent regulations.